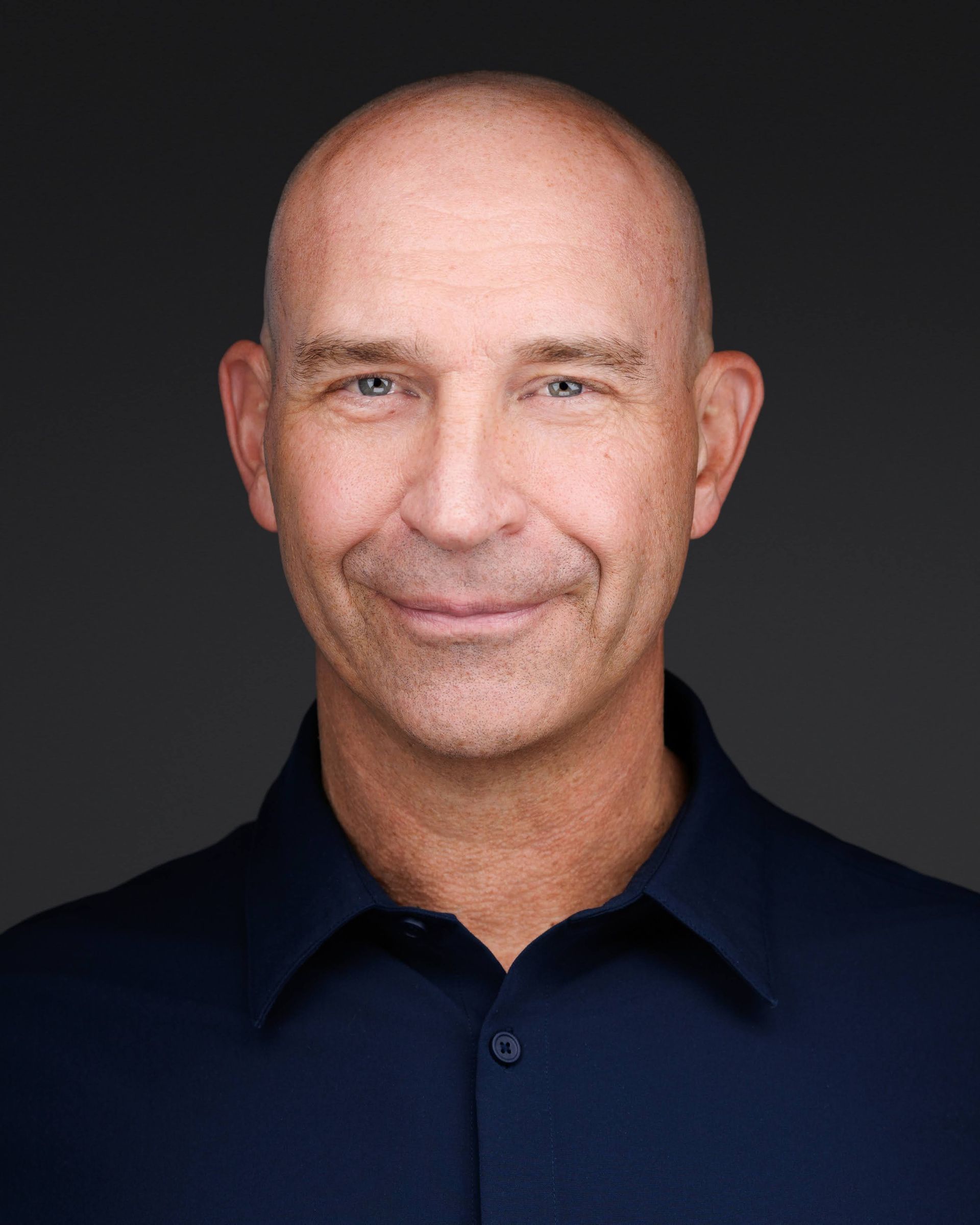

Led by Ryan Taylor, son of founder Jerry Taylor, the company has posted record revenues for the past three years and is eyeing continued success in Utah and other regional markets with a diverse portfolio and talented crews. By Bradley Fullmer

Over the course of its 50-year history, Salt Lake-based Taylor Electric has experienced myriad ups and downs—as is typical with any company plying its trade in the cyclical construction industry.

But few firms have gone through a full-blown sale, as Taylor did in 1998 when it was acquired by a national "rollup" company that ultimately became Houston-based Encompass Services Corp.—and then started back up again four years later, which proved fortuitous when Encompass filed bankruptcy in 2002.

"It's a helluva circle," quipped Ryan Taylor, 57, President of Taylor Electric and the second-generation family member to serve as the top executive, following in the footsteps of his father, Jerry, who founded the company in 1975 at age 35. "It was never planned to happen that way. We just started back up and built it to where we are now."

Under the younger Taylor's leadership over the past two decades—post Jerry's retirement—Taylor Electric has consistently been one of the top performing electrical contractors in Utah, with record annual revenues the past two years of $89 million in 2023 and $91 million in 2024, with projections of hitting the $80 million mark by the end of 2025. The past decade has been one of consistent growth and increased profitability, with Taylor saying the company posted good years even during the pandemic.

"Over the last five years, we've held steady," said Taylor, citing employee growth—now up to 300 people, including field workers and office staff—profitability, and building a strong culture as key indicators of company progress. "Ironically, we had one of our best years in 2021 [during the pandemic]. Like most businesses during that period, we were nervous, but everything turned out better than expected—we didn't miss a beat."

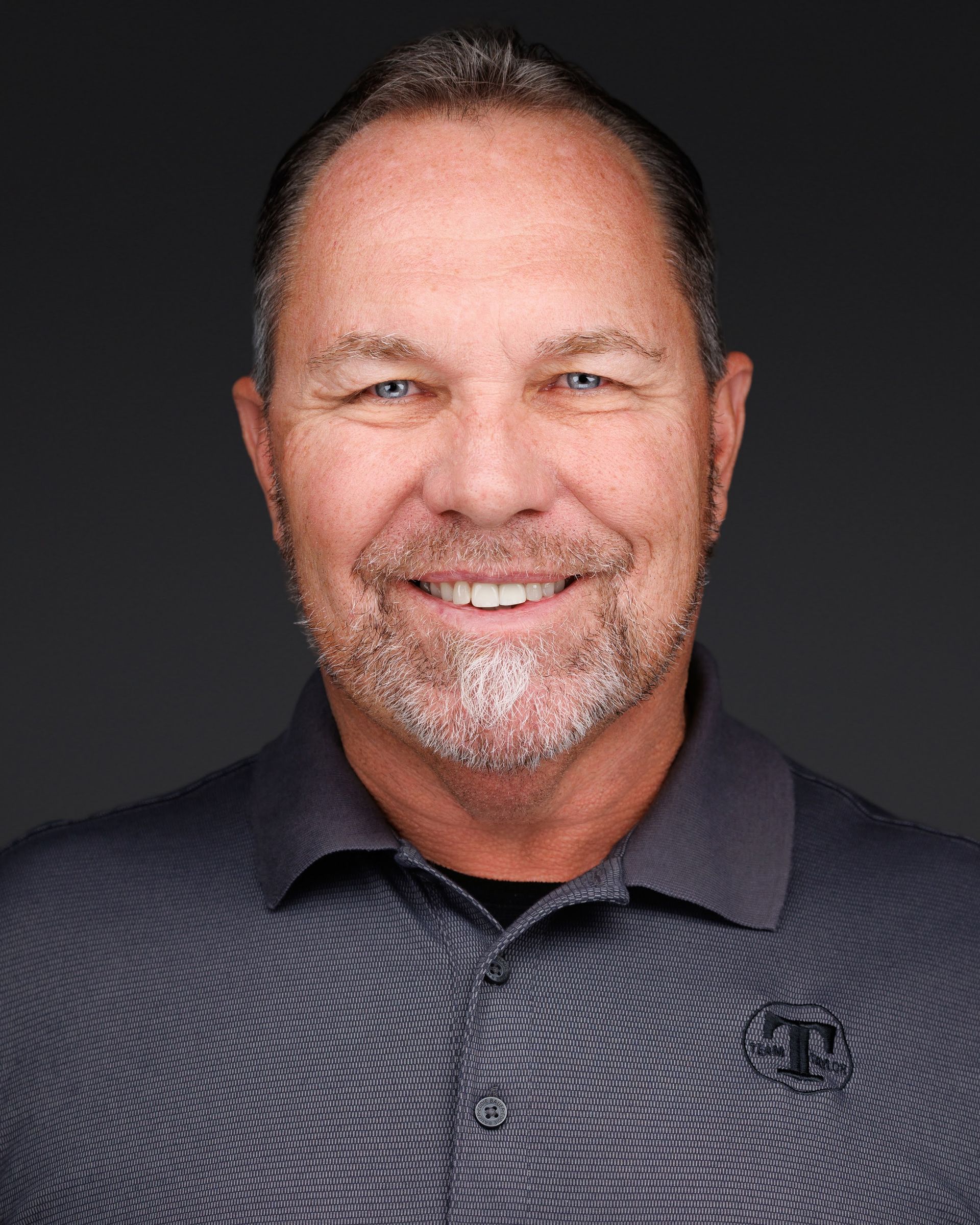

Jerry Taylor's Philosophy Centered on Hard Work, Maximizing Efficiencies

A native of Salt Lake City, Jerry Taylor grew up in a hardscrabble environment and learned the value of frugality at an early age. He attended Granite High and played football for Coach LaVell Edwards. Jerry spoke highly of his former coach and credits Edwards for helping him graduate.

"I would not have graduated high school without him," said Jerry, 85. "I had dropped out—I had an attitude back then. Two weeks later, I went back and asked the principal if I could come back, and he said ‘No.’ LaVell went to every teacher and asked if they’d give me a second chance. It got me reinstated, and the rest is history. He saved my butt."

After a stint in the military, Jerry pursued work as an electrician. He joined the union and traveled wherever there was work, and ultimately spent 13 years working for Salt Lake-based Yates Electric.

A notoriously hard worker, Jerry had gained enough confidence over 15 years to start his own company, initially called Design Electric, with little more than a pickup truck and enough tools and equipment to complete small commercial electrical jobs. After two years, Jerry had a falling out with the union and went with a merit shop policy, in addition to changing the company name to Taylor Electric.

"The early years were a little tougher," Jerry recalled. "It was just me and my tools. My mom was my first secretary—she knew how to collect money!"

Jerry credits Dee Clark, founder of Sandy-based Arco Electric, for helping him figure out labor units after leaving the union. "We were on the front edge of going non-union as a legitimate contractor. I knew how to do it right, knew how to do the electrical work. Dee Clark taught me his labor units, and I just modified them as time went on. Dee was a real thinker. To be in a competitive market like Utah, you've got to know how to be meaner and leaner."

Taylor recalled the 70s and 80s as being difficult climates to work in as a contractor because of a sluggish economy. "It was tougher, more competitive," said Jerry. "We started at the toughest time imaginable. The fact we survived made us stronger, faster, because we had to be heads up or not make it."

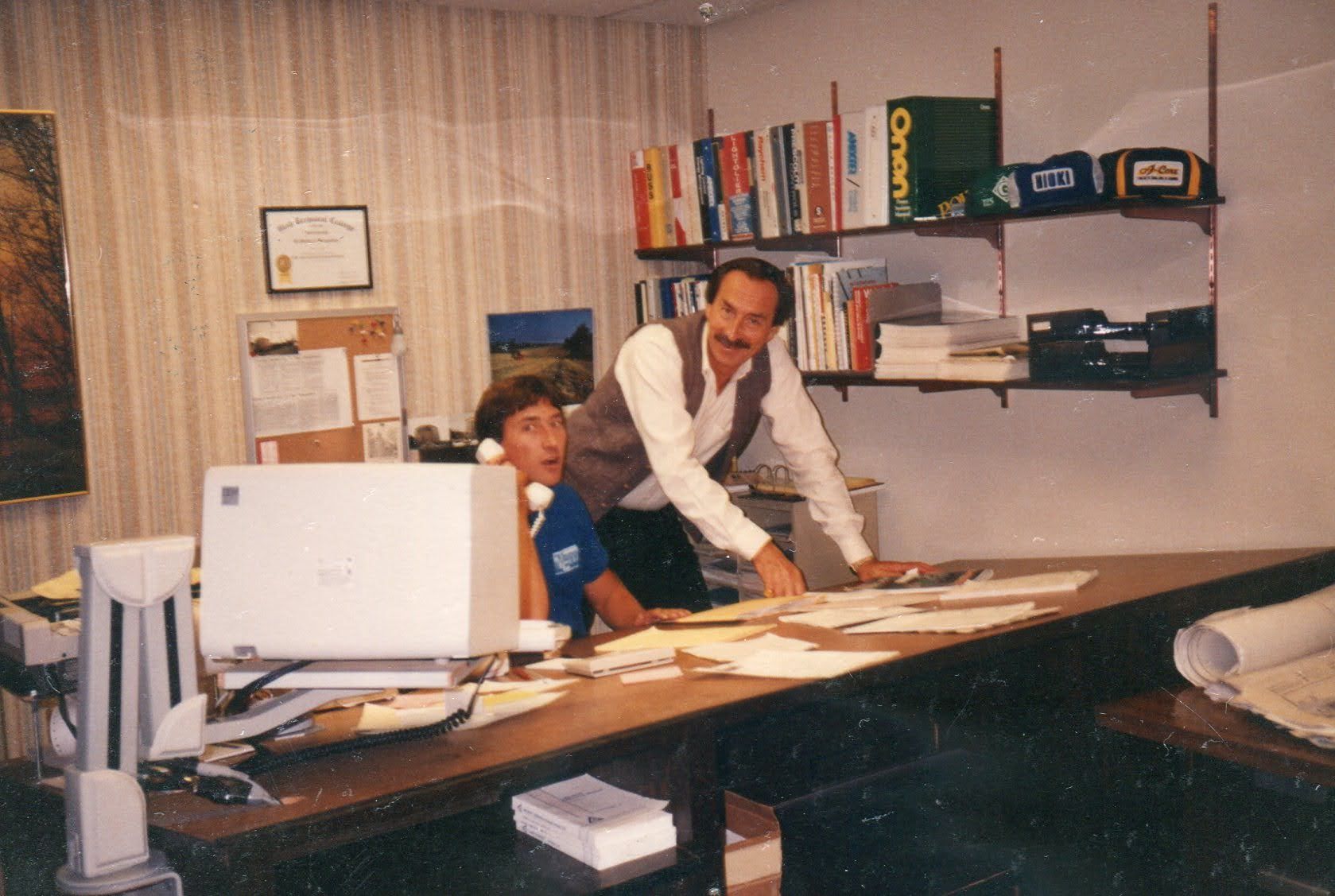

Ryan started working in his father's shop the summer after 6th grade and got to see Jerry's work ethic up close, making a valuable impression on the youngster. Beyond the routine 12 hours a day, six days a week schedule, the younger Taylor became fascinated with Jerry's meticulous nature and insistence on working efficiently. It would irk his father to no end to see workers wasting time going back and forth for tools, with the belief that wearing a beefy tool belt—regardless of how heavy and cumbersome it was—saved unprecedented time.

He also saved everything, Taylor recalled, with his early shop days spent sifting through five-gallon buckets for miscellaneous parts. "Dad had a saying in those days—'If that was a quarter, you'd pick it up.’ He grew up poor, so every penny counted. He started the company by saving everything he made and investing in penny stocks."

Jerry spent considerable time reading business journals and trade magazines, heeding advice from Wall Street investors like Warren Buffett and Charlie Munger.

"He told me he purchased one share of Berkshire Hathaway just so he could get the annual reports," said Taylor. "He felt like there was an equivalent of a college education contained in them."

Jerry was also keen on prefabrication, "long before it became popular," said Taylor. "We had an early version of a prefabrication shop. In the early days, it was looked at as taking work away from the field [workers]. My dad saw it differently—he looked at it as being efficient."

As an example, Taylor said he would cut 1/2" and 3/4" flex to a predetermined length, then push #12's through it and put connectors on each end. Prefabricated parts would be bundled and placed on pallets for ease of storage and movement on the jobsite.

By age 15, Taylor was working on jobsites, where he quickly learned the ropes, which included lighting prefab, bending conduit, and other field tasks. The next four years were essentially his apprenticeship training, as he pursued a degree at the University of Utah, earning a Bachelor of Electrical Engineering in 1994. After another year in the field, he was brought into the office to learn estimating and project management.

His first major job was the Utah Valley Regional Medical Center Women's and Children's Center addition, a $7 million contract, which was a big deal in 1996. "Most of the other estimator/project managers didn't like the big job, but that is where I feel like I excelled,” said Taylor. He also recalled landing a $14.7 million contract on the McKay-Dee Hospital in Ogden, another great project that helped him spread his wings.

Being "Taylorized"

Jerry also made shrewd hires, including men like Grant Marchant (retired in 2015), Marty Andruss (retired in 2019), Richard Harris (47-year vet, retiring at the end of 2025), Rick Blue (43-year vet), and Greg Williams (40 years in May). Taylor said Marchant essentially founded the company's estimating procedures and was a whiz with numbers. Andruss was in operations and was an expert at running field crews. Harris coined the term “Taylorized",which essentially means doing everything as efficiently as possible, particularly in the field.

Jerry would write a couple of "memos" a week, notes that Taylor said were "focused on efficiencies, like wearing your tools. It's the way you operate. We have a 20 ft. rule—don't go more than 20 ft. to get a part or tool." The company was an early adopter of utilizing handheld two-way radios and the Mikita 9-volt cordless drill. Taylor still considers two-way radios better than cell phones because radio communications are broadcast to the entire team, which can aid in troubleshooting.

Taylor said the company also operates with a unique "cradle to grave" philosophy on estimating and managing projects, with one person responsible for both estimating/landing the job and seeing it through final completion.

"There is no finger-pointing when it's all said and done," said Taylor of this approach. In addition, project superintendents and foremen are empowered to make key decisions on a jobsite. "We believe this makes us more streamlined and able to address challenges quickly and efficiently."

Creating a loyal, positive workforce and top-shelf company culture is something Jerry excelled at, said Taylor. Jerry himself had a simple philosophy when dealing with employees.

"We just treated people like I wanted to be treated," Jerry said. "We never had problems with people over the years because we treated them well. Ryan's doing the same thing. When people like you, they back you up, they support you."

Eye on Technology; Optimism High for Future Success

With a wide diversity of projects and market expertise Taylor says Healthcare has been particularly strong market over the years. "Our bread and butter is the healthcare market—that's where we excel," said Taylor. It's no secret that the rise of AI is fueling unprecedented demand for large-scale data centers. Taylor Electric has also positioned itself well in that market, with considerable experience in that sector.

Taylor added that AI is going to require more energy, with nuclear energy a likely up-and-coming market that will soon need experienced electrical designers and contractors. "The industry will need to build the infrastructure to support it." He said nuclear seems like a good option to power future data centers, but "that is a technical skill that a lot of electrical contractors may not have the expertise at this point."

Utilizing AI internally is a hot topic of discussion within the office, with Taylor saying, "We’re still in the early stages of exploration [...] how it can help us streamline what we do. I don’t look at AI as replacing anyone’s job. I look at it as a tool to supplement what we do."

Other improvements in recent years include expanding prefabrication efforts, developing a robust BIM/VDC department, and utilizing distributor partners for material warehousing and delivery.

"For a larger company, you must invest in technology—it's a given," said Taylor. "Like most, we’ve adapted technology to our trade."

The future of the company is bright, with all signs pointing to Utah's economy remaining solid, and Taylor believes his company is capable of even more. He's surrounded himself with talented, hardworking people. Top executives besides Taylor have more than 80 combined years at the company: Sheldon Dale, Vice President (hired in 1989); Dustin Sahli, Chief Operating Officer (hired in 1997); Mike Freeman, Chief Financial Officer (hired in 2006). The same principles and values that Jerry Taylor established 50 years ago remain the hallmark of Taylor Electric today. And Taylor said he's committed to keep pushing hard to ensure his company maintains its place in the A/E/C market.

"Mostly, we’ve stuck to what got us here—provide solutions to challenges, treat your employees with respect, and put customer service at the top. At the end of the day, most of what we do isn’t all that complicated."

Ryan credits his dad's example for laying the foundation of how to work hard.

"I would say my strengths are being resilient and having a strong work ethic," he said.

Jerry concurs. "Ryan works seven days a week if it’s needed," he said. "Our attitude is: we’ll do whatever it takes."

"I have a plaque on my desk, given to me by a retired estimator," Taylor added. "It says, 'Hard work beats talent, when talent doesn’t work'. I think that’s me in a nutshell."

The firm counts RiverPark Corporate Center as a long-time client (pictured), having done the electrical work on multiple office buildings in addition to providing long-term maintenance.

Taylor Electric Top Projects

Project, Location, Completed

Salt Lake City and County Building Restoration, SLC, 1989

Univ. of Utah Craig H. Neilsen Rehab Hospital, SLC, 2020

Univ. of Utah Kahlert Village Phases I & II, SLC, 2020; 2023

Myriad Genetics, SLC, 2021

Hillcrest High School, Midvale, 2021

Univ. of Utah Helix Building, SLC, 2023

Weber State Univ. Noorda Engineering Building, Ogden, 2023

Innovation Pointe Buildings 1-4, Lehi, 2023

Trager Grills Headquarters, SLC, 2023

Univ. of Utah Impact Housing, SLC, 2025

Univ. of Utah Applied Science Building, SLC, 2025