Building envelope contractors weigh in on the state of the trade—what’s working, what’s hot, and what’s changing to deliver ever-more-efficient building envelopes. By Taylor Larsen

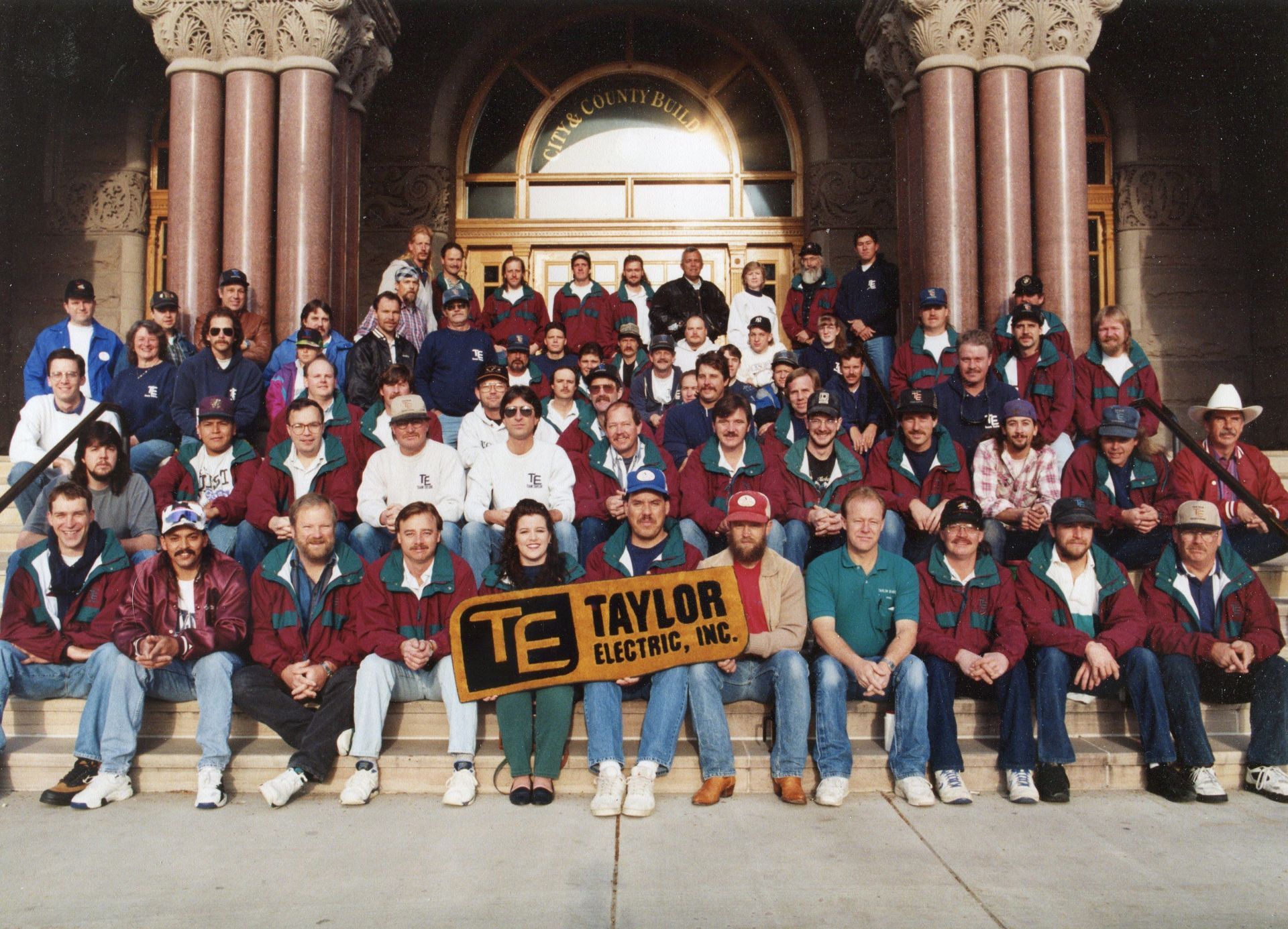

Steel Encounters (field team pictured left) is among the handful of building envelope contractors showcasing Utah’s growing expertise in delivering high-quality, highly efficient building envelope systems. Their efforts include the Mountain America Credit Union Headquarters (main image), 95 State (middle), and Huntsman’s Kathryn F. Kirk Center for Comprehensive Care and Women’s Cancers (right, all courtesy Steel Encounters).

Pushing the Envelope in Products and Approach

Glazing is a significant part of many human-centric spaces where proper installation of fenestration systems and their finishes improves dynamic and thermal performance. Prefabricating the window systems at the shop before delivery and installation isn’t a new concept, but “pre-glazing”, as it is known in the industry, is growing in importance.

Hiatt said product improvements come from including more argon in insulating glass, as well as improvements in aluminum curtain wall systems, lowering system U-Values to as low as 0.31, depending on the design. Fabricators are also improving their pre-charge technology, which alleviates the need for breather tubes and keeps argon gas where it needs to be. Utilizing this technical expertise is bringing about the practical. Said Hiatt, “façades should perform better and last longer.”

While this is good news, Hiatt cautioned that the design emphasis on U-Value or solar control may miss a larger issue: large buildings with a high percentage of vision glass will still heat up in full sun during the winter. Even when it’s below freezing outside, said Hiatt, It’s not uncommon for a south or southwest face of a glass building see the A/C come on a sunny day in February.”

He said mechanical engineers, architects, and contractors must get on the same page to correctly prioritze U-Value, SHGC, and VT so that building envelope systems can work in concert with right-sized mechanical systems.

Metal paneling will continue to be an important façade piece moving forward to drive down cost.

“Metal panels and design innovations on these buildings drive what we do,” said Rainey, “We’re trying to bring products to market that are less expensive, more desirable.”

Cladding like insulated metal panels is growing in popularity, as are argon-gas-insulated window units and ultra-thermal glazing systems that give building systems lower U-Values. While some of these changes are practical, some are decorative. Luque described it as "jewelry on the outside of the building."

Rainey explained, “We’re seeing more [designs] wanting to hang stuff on the building. You’re trying to increase the look of these buildings, but it imposes a lot of difficulties for the engineers to make it work.”

Architects are pushing the limits on glass sizes, too.

“Everybody wants one piece of glass for their entire elevation or entire opening,” said Crocker. The “open air” look may be eye-catching, but product quality, warranty, and constructability require additional consideration. As design reaches new frontiers, design teams must consider its effect on installation methods and sequencing.

“There is inherent risk when you're pushing the envelope,” Strong said, pun intended. “And it can't all be rolled down to the subcontractor.”

Mollerup Glass is another building envelope contractor with a stellar reputation for delivering top-notch glazing work. Their work on the U of U Impact & Prosperity Epicenter included creating custom splayed mullions and “pre-glazing” and installing 1,000 operable windows across the curvature-heavy project (pictured during and after construction, courtesy Mollerup Glass)

Trending Projects

Especially when the fieldwork required to deliver in today’s construction environment is more sophisticated and coordinated than ever.

“As far as construction goes, it’s a lot more coordinated,” said Crocker. “We’re all stacked on top of each other, but we’re fluid; we work well together.”

Time taken in planning and procurement may be extended, Hiatt said, but with key façade trades coordinating drawings and dimensions to ensure fit-up at installation, building envelope contractors are speeding up install times by a few months.

Early involvement, from shop drawings to engineering to procurement, “allows us to front-load our schedule a little bit,” said Crocker “We end up with a lot fewer change orders, and we usually hit the ground running.”

Those efforts have led to stellar projects, like the stunning glazing on the University of Utah’s Impact & Prosperity Epicenter. By involving Mollerup Glass early, the firm developed custom splayed mullions that allowed for segmented glazing around the building’s many curves and created 1,000 pre-glazed, operable windows ready for installation on the job site.

Adaptive reuse and renovation work are utilizing updated building envelope systems and installation methods to breathe new life into old builds. Steel Encounters recently completed the remodel of the former University Club Building into Seraph—24 stories of high-rise luxury living. The firm played a key role by replacing exterior fenestration in the tower to provide higher U-Values and solar heat gain performance.

Both Flynn Companies representatives said that Salt Lake is still a “gold mine” in terms of ongoing work as many building envelope contractors continue to prospect on upcoming projects in different sectors—higher education, healthcare, and K-12—with the latter vertical experiencing a major change in budget and involvement.

“Schools aren’t just a square building—they’re showpieces,” said Luque.

The Future of Building Envelope

Knowledge, understanding, and coordination are all improving, but those in the field continue to make the difference between a standard project and a great one.

“For our trade, it's finding trade craft workers,” said Hiatt. “Even with apprenticeship programs, it's difficult to attract young people to ours, and really all building trades.”

Finding and keeping good field workers remains challenging, especially when ongoing work goes on hold.

“You have a good crew, but you have peaks and valleys, and so what do you do with your good crew?” Strong said. “Do you lay them all off and then try to get a new crew? Is that ethical? Is that right?”

But employment costs are rising in the office, too.

“Over the last few years, we've really had to increase our staff, too,” said Strong. Where it was once just a project manager assisting a field team, increased risk levels mean more staff to mitigate it—engineering, drafting, additional foreman—and prioritizing projects that require a higher level of expertise.

Solving that problem will require that preconstruction lose the “free construction” nickname, where, again, earlier contractual agreements mean shared risk and reward, and better industry norms are established.

Although there are many challenges and opportunities ahead for the building envelope trade, the best way to make a difference today is from the jump—the meeting just started.