Engineers from structural firms around the state weigh in on what’s new. By B. Garn

The continued spread of and improvements to BIM, new fuse plate technology, and the rise of mass timber are a few of the topics shaking up structural engineering in the Beehive State. Utah Construction + Design reached out to some Utah’s leading structural engineering firms to find out about current trends, technologies, and with five years of reflection, how are owners and designers looking at and learning from the 5.7 magnitude earthquake that shook the Wasatch Front in spring 2020.

Jerod Johnson, Senior Principal at Reaveley Engineers, wrote a detailed retrospective of the event in 2023 and says researchers and engineers learned a few things from the quake from how different building types responded to insights into the geology of our region.

“Research has revealed that the shape of the Wasatch Fault is different from what was previously believed. The Magna earthquake, initially thought to have occurred on a fault in the western part of the Salt Lake Valley, actually took place on the Wasatch Fault. The fault extends into the valley at a much shallower angle than expected, rather than descending steeply from the toe of the mountain.

This new understanding of the fault's geometry has significant implications for seismic design and building codes. We anticipate changes to the spectral acceleration maps used in structural design.

The lateral shaking observed during the 5.7 magnitude earthquake was much higher than expected,” says Johnson. “It highlighted the need for updated design practices that account for this amplification. These findings will influence future building codes and practices in Utah, ensuring that structures are better equipped to withstand such events.”

But Chris Hofheins, a Senior Principal at BHB Structural, is concerned the wider public may not have learned enough from the event.

“Most structural engineers thought the earthquake would be a wakeup call but to a large degree I think it had the opposite effect,” said Hofheins. “People looked around and felt like it wasn’t so bad and we’ll be alright if something bigger hits. We’ve seen a few owners who decided to increase the seismic safety of their buildings but we’re also seeing the opposite where I think some people are overconfident.”

Blowing a Fuse

Structural resilience, designing buildings that not only protect those inside during a seismic event but can be quickly reoccupied, continues to be of great interest to structural engineers. Replaceable fuses, or structural sections that can be sacrificed dissipating energy during a seismic event and then replaced, have continued to gain popularity with designers and improve the resilience of buildings.

“This innovation represents a significant shift from traditional methods of enhancing ductility in earthquake design. Instead of merely adapting existing practices, replaceable fuses offer a new paradigm for building resilience,” said Dorian Adams, Senior principal and President with Reaveley Engineers.

Adams said fuse technology like buckling restrained braces (BRBs) have been available and widely adopted for several decades. Newer proprietary systems like Durafuse, among others, for moment frames have been gaining popularity.

“New technologies are emerging that offer exciting possibilities. One such innovation is the SpeedCore steel shear wall with a concrete core, which is included in the new AISC seismic provisions, the 2022 edition. This technology represents a significant advancement in seismic design,” said Adams.

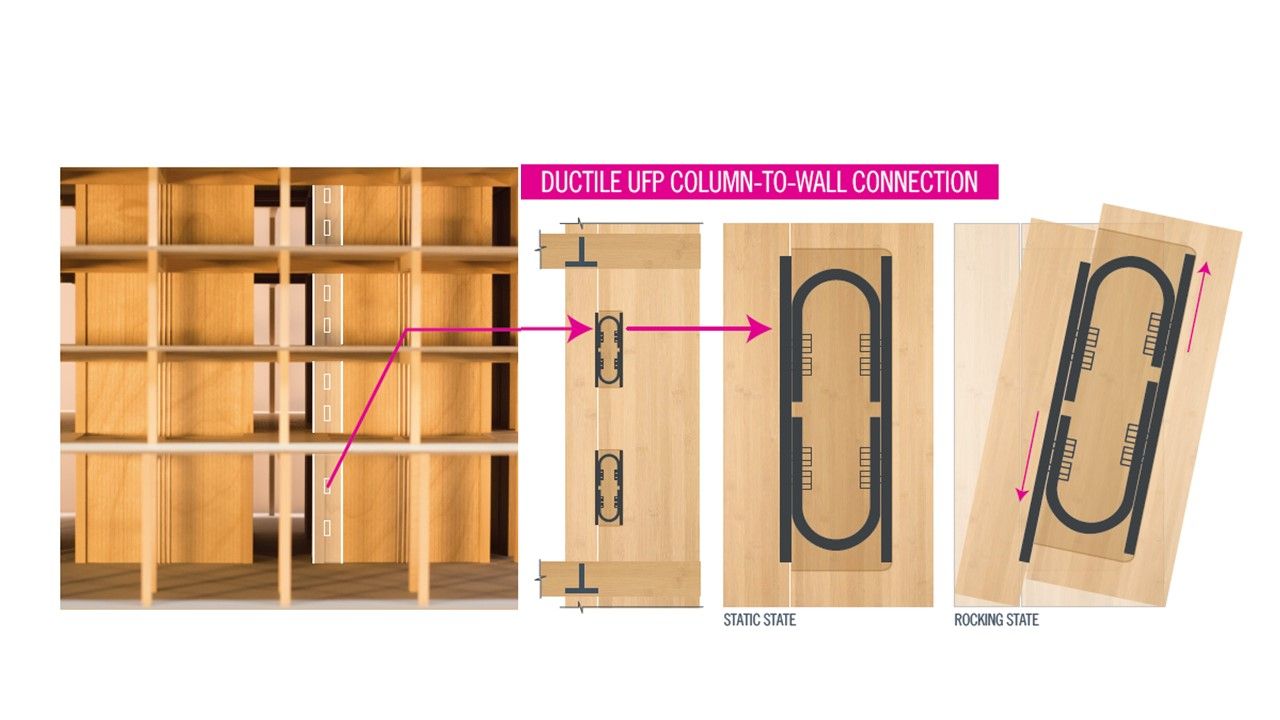

Replaceable fuse technology is also being employed with mass timber construction as interest in and use of the material around the world continues to grow.

Jordan Terry, Principal at KPFF Consulting Engineers has designed structural systems for several mass timber and mass timber hybrid projects such as the ICCU Arena at the University of Idaho in Moscow and the recently completed Portland International Airport Terminal Core Redevelopment with its 400,000 sq ft mass Cross Laminated Timber (CLT) roof. He said there have been important advances recently in seismic systems for mass timber structures.

“Typically, when you get a mass timber building over five stories you have to look at the seismic reinforcing and that is where you introduce something other than just timber. You might have a concrete core with the elevator shafts or use BRBs,” Terry said. “We had a client in Portland that absolutely wanted to use as much timber as possible. We helped develop a new system called a rocking CLT core wall. The base of the shear wall panels isn’t connected to the ground and it can rock back and forth but there are energy-dissipating sections or fuses, between the panels. They are very ductile. You swap them out and it’s as good as new.”

David Dunn, CEO and principal at Dunn Associates, said the firm had utilized a rocking CLT shear panel in their design for a new all mass timber building currently under construction for the Zion National Park Discovery Center at the national park’s east entrance.

Terry also said the firm was assisting researchers at the University of California San Diego in developing more all-timber lateral systems but noted like all materials, it should be used for its strengths.

“CLT is really strong and stiff so you’d think it would be great for seismic reinforcement, but it is not very ductile,” he said. “We have a project in Spokane [Washington] where we used BRBs. We are letting the wood be stiff and strong like it wants to be and letting the BRBs deal with dissipation.”

Hofheins noted mass timber research is going on here at the University of Utah as well. Dr. Chris Pantelides and the U of U’s Department of Civil and Environmental Engineering are developing a BRB encased in timber.

Adams noted Dr. Pantelides’s project is not the only fuse research underway locally.

“One such project involved a device placed in the middle of an X brace, with elastic braces and a fuse at the intersection of the diagonal braces. This device would compress and stretch, cycling through combined flexure and shear,” he said. “A University of Utah PhD candidate recently further enhanced this concept in his dissertation, adding curved plates of steel that cross one another and engage in tension only after reaching a certain threshold of displacement. This supplemental strength activates only when needed, providing a dual-level design solution that accommodates different magnitudes of earthquakes. The idea of replaceable fuses holds significant potential for the future of structural design. These innovations will become an integral part of performance-based seismic design, offering tailored solutions for varying seismic events. Simpson's Yield-Link connection is another example of this technology, although it is currently more suited for smaller applications.”

Dunn said making buildings resilient and potentially reusable quickly after a seismic event not only has implications for safety but for sustainability as well.

“Designing resilient structures is really an environmental consideration that is undervalued in my view,” said Dunn. “Code-based buildings will undergo massive deformations and damage after an earthquake. Sometimes small, incremental increases in first-costs can make huge differences in anticipated building performance, salvaging buildings that would otherwise be landfilled. That is a huge environmental impact, but not as buzzy as bike racks, low-water urinals, solar panels, etc.”

Cross Laminated Timber (CLT) is gaining momentum in various design and structural applications throughout the West. (top-right) Exposed beams provide a bold engineering statement at the Idaho Central Credit Union Arena in Moscow, Idaho (photo courtesy KPFF). Renderings of a rocking CLT wall system illustrate how fuses help to dissipate energy in a seismic event (renderings by Lever Architects). Traditional steel structural systems are shown (left) in this under construction image (photo courtesy Dunn Associates, Inc.)

Tech Talk

The designers who spoke to UD+D agreed the use of BIM software continues to grow and is being utilized by more segments of the A/E/C industry.

“Revit is an incredible tool for us and all designers,” said Jeremy Achter, a Vice President and Senior Principal with ARW Engineers. Achter is also the 2025 President of the Utah Structural Engineering Association. “When everyone on the team uses Revit with clash detection it helps address a lot of issues that tend to come up and we can solve things before we put them into drawings. We are always hoping smaller firms and contractors will join the BIM bandwagon.”

Hofheins said he has noticed more contractors and subcontractors utilizing the technology.

“That engagement [using BIM] becomes really crucial now when structural designs are produced so much earlier than work from other disciplines.”

He said using BIM can help all the members of the team have more certainty about things like materials.

“It [material price uncertainty] has been a trend the last few years since the pandemic and certainly with the current environment with tariffs and not knowing how it will play out, procurement of materials early in the process is even more important,” he said.

Reggie Harris, Senior Principal and BIM/CAD Manager for Reaveley Engineers, noted BIM technology does have challenges.

“While BIM promotes a collaborative work environment, one of the biggest challenges in BIM workflows can be the transfer of information between the engineering design model and the production model,” he said. “Interoperability between different software platforms can sometimes cause issues when transferring data back and forth between those software platforms. Additionally, performance issues with software and hardware can occur, especially when handling the large datasets required by the design and production models."

Artificial intelligence is making waves in the structural engineering world just as it is nearly everywhere else.

Travis Brackus, Principal and CEO of BHB Structural, said AI is something all firms need to stay informed of and learn to utilize.

“AI won’t replace structural engineers, but engineers that use AI will replace those that don’t,” he said.

Dunn said as AI advances, it is important for engineers to lean on what makes them different and valuable.

“Our ability to be trusted advisors and consultants and help connect people is something technology can’t replace,” he said. “People can ask an AI any question and get a response that could be as good or better than what we can provide but they don’t always know the right question. How do we provide that personal touch and creativity? I think that will differentiate firms going forward.”

Projects like Millcreek City Hall (top left; courtesy BHB Engineers), U of U Impact and Prosperity Epicenter (bottom left; courtesy BHB Engineers), Baltic Pointe (center, courtesy BHB Engineers), and Hill Air Force Base Museum Expansion (right, courtesy Dunn Associates, Inc.) are a few examples of many that showcase engineering and design ingenuity within the Beehive State.