A Century after its founding by Danish immigrant Soren Jacobsen, Jacobsen Construction remains a major mover and shaker in the A/E/C industry throughout Utah and the western U.S. By Brad Fullmer

A few years before the turn of the 21st Century, and with his tenure as the top executive of his family’s sizeable and well-respected general contracting firm winding down, Ted M. Jacobsen made a uniquely strategic—and incredibly selfless—decision to change the structure of Salt Lake-based Jacobsen Construction from a family-owned business to one wholly owned by its employees.

Referred to as an ESOP—Employee Stock Ownership Plan—this unique employee-owned business model stands as one of the most important decisions Ted Jacobsen ever made during his influential 40-plus-year career. As Jacobsen Construction celebrates the mother of all corporate milestones this year—its 100th anniversary—Jacobsen knows he made the right decision in guaranteeing that his family’s legacy of construction excellence will carry on well into the future.

“At one point my wife and I owned 98.3% of the company before we began transferring ownership in the 1990s,” said Jacobsen, 81. His decision dates back to 1989, when he initially started pondering company transition options. “We went from that ownership arrangement to having the stock held by some of the key employees, then to having it held by virtually every employee to some degree or another. When I retired in 2005, I sold all my remaining stock back to the company. When you leave the company, you must sell your stock back. That was very purposeful—you don’t want to have a bunch of stockholders who aren’t in the fight down in the trenches.”

Lonnie Bullard, former President/CEO and current Chairman of the Board, said having the firm become an ESOP was a brilliantly executed move, one that allowed Jacobsen Construction to maintain its relevance and continue flourishing in the Utah market and throughout the western U.S.

“There aren’t a lot of companies that make it to 100 years,” said Bullard, 66, who currently serves as Chairman of the Board of Directors and maintains an integral role in mentoring new company executives. “We didn’t get swallowed up by a big conglomerate. It’s unusual to go past three generations of ownership, and the move from family ownership to an ESOP structure was not easy to do. Ted’s commitment to make it an employee-owned company is special—we couldn’t have done it without him.”

Jacobsen initially learned about the ESOP program on a visit to a Seattle-based general contractor. “I went out to a job site and met one of their project managers,” Jacobsen recalled. “I’m guessing he didn’t have a college degree, but he had a lot money set up in his ESOP account as a result of having been in the company for a long time. I remember thinking, ‘That’s the kind of guy that makes the company go, and that’s what I want.’ I didn’t need millions of dollars in my own bank account. I felt like in all fairness, moving toward employee ownership motivates people because it becomes their company instead of Ted’s company. So, the 2 x 4 on the ground belongs to him, or the pickup truck is partly his.”

“Ted’s attitude and desire to have employees benefit from the success of the company was huge,” said Doug Welling, 66, who retired on January 1, 2021, after 34 years at Jacobsen, including serving as CEO for more than eight years and President for more than 14 years. “He wanted an ownership group that could move forward. The power of people being owners of a company, and invested in doing a good job, is real.”

“Our company structure as an ESOP helps us consistently make the best long-term decisions,” added Gary Ellis, current President/CEO. “We’re not in it for the quick dollar. We believe in doing business the right way and growing Jacobsen Construction for many years to come.”

“It seemed like a win-win for the employees, and it seemed like in the future it would do nothing but improve their loyalty and determination to do well,” added Jacobsen. “There are a lot of Jacobsen employees who have done very well devoting their careers to the company. I think that’s just wonderful.”

Company Origins

A native of Denmark, Soren Jacobsen lost his father in a windmill accident at the age of one and grew up as an only child, raised by his mother and stepfather. He emigrated from Denmark at 18 in 1900, settling in Iowa.

After several years working in Iowa, Soren met another Danish carpenter, and the pair decided to move to Seattle. They boarded a train from Omaha, but Soren ran out of money in Salt Lake City and thought he better work in Utah for a while.

Soren eventually met a striking Norwegian girl named Anna Jensen who caught his eye. They dated for a time, with Soren moving to California to chase work following the Great San Francisco Earthquake of 1906.

“He was bright enough to realize there would be a lot of building/rebuilding opportunities,” said Jacobsen.

Soren landed work initially at a cabinet shop, then became a sub-carpenter foreman overseeing 40 carpenters on the rebuilding of the Fairmont Hotel. He maintained communication with Anna, and the couple married in 1908, living in San Francisco until 1911. Soren’s time on the West Coast was highly educational. He served as a concrete superintendent on the rebuild of the Fairmont Hotel, which was key for him, as he learned to work with reinforced concrete, a relatively new construction method at the time.

“They hired him [on the Fairmont] to do something he had never done before; he was excited,” said Jacobsen. “He was a good learner, and his experience there with reinforced concrete was very helpful when they moved back to Salt Lake after a couple of years.”

A decade after Soren and Anna moved back to Utah, he struck out on his own and founded Jacobsen Construction in 1922. The company built several prominent buildings over the next 20 years, including the original Primary Children’s Hospital, the Deseret News Building, and—the highlight of his career—the Los Angeles for the Church of Jesus Christ of Latter-day Saints.

Ted Jacobsen said his grandfather was a people person first and foremost—with experience forged by working with a host of different types of people in post-earthquake San Francisco, which taught him compassion for others.

“He knew what he was doing—he had a good business mind,” said Jacobsen. “He was congenial. People liked him; people came to trust him.”

A Perennial Top Utah General Contractor

Soren’s sons, Leo and Ted C., inherited their father’s passion for construction and were instrumental in helping lead the firm from the time they became full-fledged partners in the early 1940s until their retirements in the 1970s. Under their watch, Jacobsen Construction built a reputation as a no-nonsense contractor that delivered quality projects on time and on budget. It’s a reputation that the company is careful to maintain to this day.

Jacobsen Construction has perennially ranked No. 4 among Utah-based general contractors since 2010 (per UC&D annual Top Utah GC rankings) with revenues over half a billion dollars annually for the past several years, including a record $746 million in 2021.

The firm provides an array of top-shelf services/delivery methods, including CM at-risk, preconstruction, CM/GC, design-build, green building/LEED, BIM, and self-performed work including carpentry and concrete. Its markets span nearly every project type: government/institutional, religious, healthcare, multi-family, commercial office, sports and recreation, retail, hospitality, mixed-use, and education. Its list of notable projects is lengthy and includes many iconic, once-in-a-generation projects.

Some of the firm’s once-in-a-generation projects include (opposite page, clockwise from top left): the iconic Salt Lake Temple, which is undergoing a complex restoration and seismic retrofit, along with the construction of a new visitor’s center (courtesy Church Newsroom); the Utah State Capitol Restoration (interior view of the fabled rotunda); the mammoth 1.4 million SF Conference Center for the Church of Jesus Christ of Latter-day Saints (a JV project completed in 2000); the magnificent 775-room, five-star Grand America Hotel (a JV project completed in 2001, photo courtesy Jacobsen Construction).

New Paragraph

Generations of Leaders Share Common Traits of Hard Work, Competitive Drive

Ted M. Jacobsen—President 1974–1996; Chairman 1996–2005

Ted M. Jacobsen learned the construction business initially from his father, Leo, but became a seasoned professional under the tutelage of his uncle, Ted C. Jacobsen, his namesake. Born in 1940, Jacobsen remembered his father taking him on a project as a five-year-old at the Dugway Proving Grounds where his dad ran a grader on a dirt road. He said his grandfather Soren was “always very kind to me and approachable.”

Leo and his wife, Rosebud, had four children, including three boys. Ted M. was the only one to work for the family business long-term. His parents expected their children “to get good grades—we needed to learn interpersonal skills as well,” said Jacobsen. He worked summers as a youth doing various jobs, including building precast concrete columns in the construction yard, before graduating from East High in Salt Lake. He then attended Stanford for two-plus years before leaving on a religious mission to Scotland from 1961–1963.

He earned a Bachelor of Civil Engineering at the University of Utah and went back to Stanford for a Master of Construction Management, graduating in 1966.

Jacobsen admitted he “didn’t want to work for the family business—I wanted to go out in the real world to see if I could make it.” He accepted a job as a project engineer with DuPont in Victoria, Texas in February 1966. A month later, he got a call from his dad. Leo Jacobsen was called to serve as a mission president in Norway for the Church of Jesus Christ of Latter-day Saints and informed his son Ted that he needed to come back to Salt Lake and help his uncle with the family business—no questions asked.

“My uncle was really my mentor,” Ted M. said. “He was important in helping me get my feet on the ground.”

Ted C. was a stickler for detail and demanded excellence in the projects his employees built. “The superintendents would say he could see a problem two blocks before he got to the job—he had a very keen eye,” said Jacobsen.

Shortly after Ted M. started working full-time, his uncle assigned him to perform manual labor on a small project on the Goggin Drain, on the margins of the Great Salt Lake. It was winter, so working conditions were less than favorable. He worked with a shovel ahead of a grader, ran the grader and a crawler/loader, and did other physically taxing work.

“At the time, I thought, ‘What is my uncle doing this for?'” Jacobsen said. “I had a master’s from Stanford. But it was very helpful. I learned the impact on human beings that comes with working in cold weather. I wasn’t there very long, but I chuckle at it.”

Jacobsen worked as an estimator for 18 months and as a project manager for a high school project on the north end of Lake Tahoe before being called to help the company with other executive-level work.

He would soon develop his own critical eye and attention to detail that had made his uncle such an effective company leader. He also learned the value of the English language, especially when it came to crafting contract documents.

“I tried to write with exactness, so when we would write a sentence, there was only one possible interpretation,” he said. “An important letter would go through five or ten or even more drafts. We worked very hard to have contracts that were crystal clear; we tried to eliminate ambiguity.”

Ted M. Jacobsen took over for his uncle as President in 1974 at the relatively youthful age of 33. The company wasn’t very big at the time, with annual revenues in the $4–$5 million range.

“Soren started it, and my dad and Uncle Ted were second generation and did a good job,” he said. “There is sort of a legend that in the third and fourth generation, the ship is sunk—somebody inherited the keys to the office but didn’t have the right skills and so on. I was quite determined not to wreck it.”

Jacobsen guided the company through the glum 1980s, a period marked by the nationwide Savings and Loan Crisis. Gradually, the construction climate in Utah improved, and Jacobsen Construction began to flourish in the 1990s and beyond.

“Things cycle and we had to adjust to those [periods],” he said. “There eventually came a significant economic wave to the Salt Lake Valley and Utah in general—we managed to catch that wave. To do that, [we] had to grow in terms of people and financial capacity. Growing is not a low-risk thing—you have to train people to do things the way you want things done. We hired a lot of wonderful people who have played their role well.”

Lonnie Bullard—President 1996–2006; CEO 1996–2012; Chairman 2005–Present

A native of Roy, Lonnie Bullard is a descendant of Archibald Gardner and member of the well-known Gardner family. He started his professional career in finance after graduating with an MBA from Northwestern in 1980. He worked on Wall Street for four years before joining Salt Lake-based Boyer Company in 1985, doing project financing for company founder Roger Boyer.

In 1996, Bullard joined Jacobsen Construction. Despite not having a traditional construction background, he thrived in the position and led the company to new heights, overseeing the completion of several hallmark projects.

“He didn’t have much in the way of construction experience, but he has a good mind, and he’s a very likeable human being,” said Jacobsen. “He’s energetic, and he’s a fierce competitor.”

Bullard didn’t know what to expect in transitioning to the world of construction but was excited at the prospect of leading one of the state’s biggest general contractors.

“You move forward and hope for the very best,” said Bullard. “I appreciate Ted bringing me on—it was difficult bringing in a President/CEO from the outside. It was a leap of faith on his part, a leap of faith on mine, but I’m grateful he would entrust me with his company in that manner.”

The first major project under Bullard’s watch was the Conference Center of the Church of Jesus Christ of Latter-day Saints. Today, the mammoth, 1.4 million-SF building seats over 21,000 in its main auditorium and is believed to be the largest theater-style auditorium ever built. Jacobsen Construction teamed with Utah-based firms Okland Construction and Layton Construction to form the Legacy Contractors joint-venture, which delivered the building in time for the April 2000 session of the Church’s general conference.

“We had a good partnership,” said Bullard. “Everyone took their company hat off and put on a project hat. We didn’t separate the project; we integrated our teams into one team.”

Bullard focused much of his energy on establishing and maintaining a positive work culture.

“Our goal was to embrace the culture established by the Jacobsen family and never give Ted a reason to be embarrassed,” he said. “A reputation can be lost in the blink of an eye.”

Bullard added that the employees are unquestionably the firm’s main asset.

“We’re not an asset-rich company—we’re a company where the assets are people,” he said. “While I like the fact that Jacobsen has been involved in iconic construction projects along the Wasatch Front, that’s not what I have focused on. I get more enjoyment and more good feelings out of watching people grow, seeing the tremendous talents of people blossom.”

Doug Welling—President 2006–2020; CEO 2012–2021

Welling was raised in Davis County by prominent educators Lawrence and Kathryn Welling. He naturally gravitated to construction and worked as a laborer and carpenter while attending college at Brigham Young University, where he graduated with a Bachelor of Construction Management in 1981. He gained experience as a project manager for a drywall subcontractor and a general contractor while in Houston, then as a project engineer on a hydroelectric project near Boise before arriving at Jacobsen in 1987.

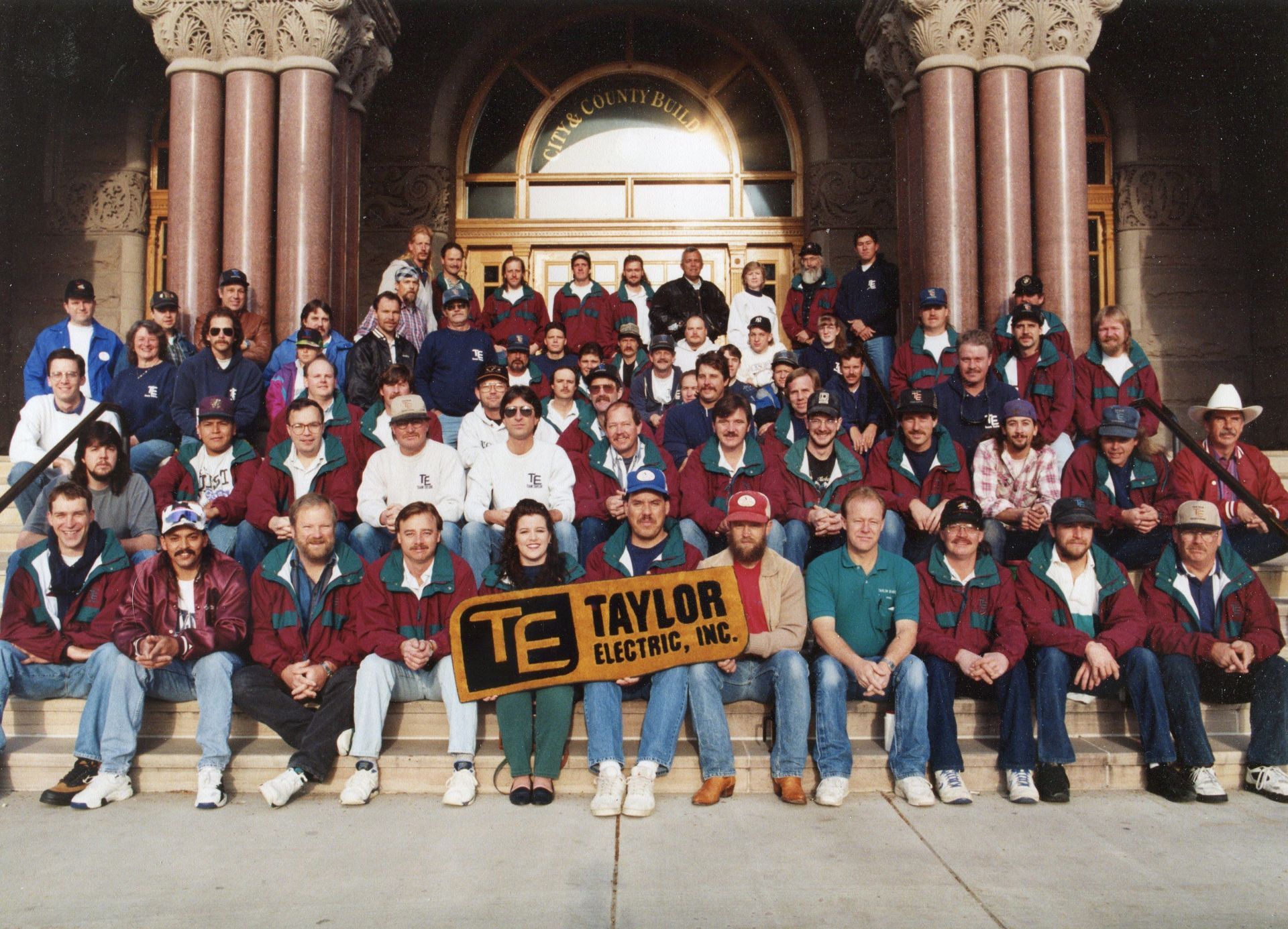

Jacobsen Construction hired Welling as a project engineer on the seismic retrofit project for the Salt Lake City and County Building, the first-ever base isolation of an existing building in the world.

“As a company, we get into very challenging engineering projects,” said Welling, who was tasked with figuring out the project schedule so Jacobsen could secure its first million-dollar payment from the owner.

There were essentially three phases to the complex project: exterior, interior, and base isolation. The exterior work called for all stone to be strengthened or replaced. The interior scope included caring for historic plaster, paint, flooring, and other delicate items. The base isolation portion required the installation of 447 lead/rubber isolators underneath the building. The building is isolated from the surrounding ground by a perimeter moat wall that allows for lateral movement during a seismic event.

“I was able to put a schedule together that reflected the intricate sequencing of the project—the team worked wonderfully together,” said Welling. “You can draw a straight line from that project to the complex seismic work we’re able to do today on other buildings.”

Jacobsen has constructed other significant historic seismic renovation projects, including the Salt Lake Tabernacle, the Provo City Center Temple, and the $220-million Utah State Capitol Seismic Retrofit (2004-–2008), highlighted by 265 base isolators installed as part of its overall restoration. The current renovation and base isolation of the iconic Salt Lake Temple is perhaps the most prominent example of Jacobsen’s base isolation expertise. The Salt Lake Temple is the most historically recognizable structure of the Church of Jesus Christ of Latter-day Saints and one that, when its renovation finishes, “will stand as nothing short of an engineering and construction marvel,” according to Welling.

He agreed with Bullard that Jacobsen’s employees are the primary reason for the firm’s past and current success.

“This company is full of driven people—birds of a feather flock together,” he said. “Our employees are driven, respectful, successful, kind people. We have always been very interested in being the best we can be and taking care of clients. If we did that, we would be invited back. We have amazing long-term clients that give us very difficult projects.”

In addition to Jacobsen employees, Welling said the firm would not be where it is without the support of many great partners over the years, including subcontractors, suppliers, owners, architects, bankers, sureties, and craftworkers.

“All have joined together to create legacy projects through grit, sacrifice, and determination, and their work will stand tall throughout the coming decades,” he said.

Welling said seeing the firm celebrate 100 years in 2022 is monumental.

“I had the thrill to work at Jacobsen for a third of its history—what a tremendous opportunity for me to see our expertise and relationships grow,” he said. As President/CEO of Jacobsen, my desire was to add to the momentum and luster of the Jacobsen legacy. I really feel like we did that.”

Gary Ellis—President June 2020–Present; CEO January 2021–Present

Gary Ellis, 52 and born in Holladay, comes from a finance background just like Bullard. Ellis earned a Master of Accounting from BYU in 1995 and spent five years at KPMG’s Salt Lake office, which he described as a “terrific experience working for great people” in many different industries.

Ellis started at Jacobsen in 2000 as Controller, spending many hours his first couple of years acclimating to the ins and outs of construction. He was mentored by long-time CFO Richard Kirkham, along with others. He knows he has big shoes to fill but understands that the key is simply relying on the bevy of top-notch professionals who help guide the firm’s 650-plus employees.

“The biggest challenge going in was feeling the need to know everything, and then the recognition that, no, you don’t need to know everything,” said Ellis. “I am surrounded by a seasoned team that lives our core values and who know the industry inside and out. That has been a fun realization. We make much better decisions collaborating and relying on one another’s expertise.”

A focus of his first year as President was making sure everybody on the executive team felt safe communicating their ideas and collaborating, and then conducting strategic planning to set up the company for future success.

Ellis is carrying on a proud and extensive tradition of Jacobsen Construction’s close involvement with the AGC of Utah, where he currently serves on the Board of Directors. Five of Jacobsen’s Presidents served as President (later named Chairman) of the venerable construction association, including Soren (1926), Ted C. (1946), Ted M. (1982), Bullard (2008) and Welling (2018).

“In the construction industry, it’s rare a family business can last 100 years—it’s a testament to their core values,” said Rich Thorn, AGC of Utah President/CEO. “They are known for giving back to the community. They helped build the AGC of Utah headquarters and our training center, and the list goes on and on. They don’t live for the moment—they know it’s a marathon, not a sprint. Their reputation means everything to them. Owners automatically have a high degree of confidence and trust in them.”

Ellis is confident in the firm’s bright outlook as it embarks on its next 100 years.

“We don’t have a goal to be the largest contractor in Utah. We have aspirational goals to be the best contractor in the marketplaces in which we do business, and to provide stellar service,” Ellis said. “That is truly who we are and what we believe. We believe in building for the life that will go on in the facilities we build—the places where people will worship, where they will learn, where they live and play. I like to call it the ‘wow factor,' where we can step back and say, ‘Wow, look at what we left behind for that community or for that client.’ If we can keep doing that, we’ll continue to see long-term success. That’s our vision.”

The Provo City Center Temple was another supremely complex and challenging restoration project that won numerous local and national awards (completed in 2015). The Amangani Resort in Jackson Hole, Wyo., illustrates the firm’s high-end resort chops (photos courtesy Jacobsen Construction). Jacobsen restored the Salt Lake City and County Building (originally completed in 1894) in the late 1980s, believed to be the first-ever seismic base isolation of an existing historic structure in the world. The isolation system consists of 443 lead-rubber isolators installed under the building on top of existing spread footings. The building is isolated from the ground by a perimeter moat wall, permitting lateral movement during an earthquake (photo by Dana Sohm, Sohm Photografx).

Significant Jacobsen Construction Projects

Project

Location

Year Completed

Primary Children’s Hospital Salt Lake City N/A

Los Angeles Temple Los Angeles 1956

Jon M. Huntsman Center Salt Lake City 1969

Salt Lake City & County Building Salt Lake City 1989

Seismic Base Isolation

Jon M. Huntsman Cancer Center Salt Lake City 1998; 2017

Phases I & IV

Amangani Resort Jackson Hole 1998

Conference Center (JV) Salt Lake City 2000

Grand America Hotel (JV) Salt Lake City 2001

Utah State Capitol Seismic Salt Lake City 2007

Base Isolation/Restoration

Salt Lake Tabernacle Salt Lake City 2008

Seismic Upgrade

Provo City Center Temple Provo 2015

Jacobsen Construction Leaders

Soren M. Jacobsen President (1922–1951)

Ted C. Jacobsen President (1951–1956; 1966–1974)

Leo M. Jacobsen President (1956–1966)

Ted M. Jacobsen President (1974–1996); Chairman (1996–2005)

Lonnie M. Bullard President (1996–2006); CEO (1996–2012); Chairman (2005–Present)

Douglas C. Welling President (2006–2020); CEO (2012–2021)

Gary Ellis President (2020–Present); CEO (2021–Present)